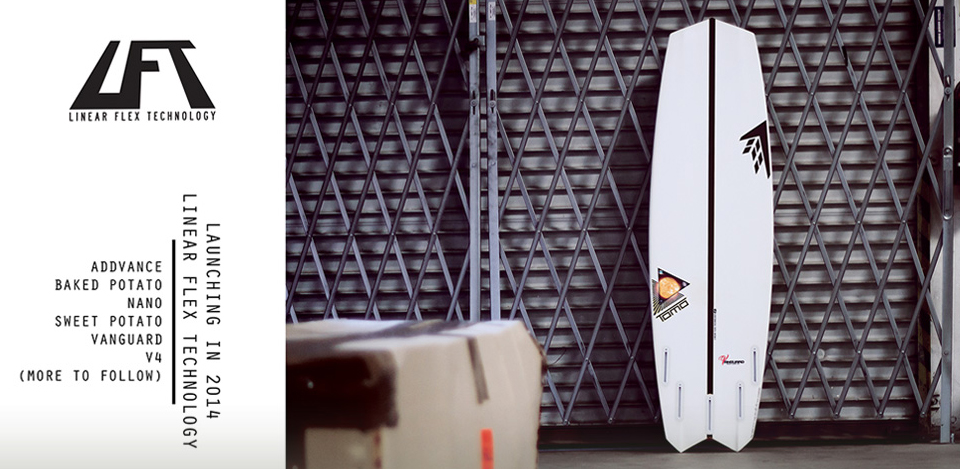

Firewire Launches Linear Flex Technology (LFT)

Firewire’s product development is focused on three things: exclusively using epoxy resin and EPS foam cores, achieving lighter and stronger surfboards through sandwich construction, and optimizing flex to enhance performance. Though LINEAR FLEX TECHNOLOGY (LFT) may appear to be a simple construction employing familiar design philosophies found in traditionally built surfboards, nothing could be further from the truth.

LFT incorporates Firewire’s new SPRINGER HD, a 0.75” (18 mm) wide aerospace composite that runs down the centerline of the board, representing the next generation in our SPRINGER technology. Unlike the original balsa SPRINGER build which only added stiffness under the front foot, the SPRINGER HD runs the entire length of the board and plays a pivotal role in optimizing flex from nose to tail.

Inserting a high-density material down the center of the board does create engineering hurdles. For example, deck compression over the SPRINGER HD would be less than the surrounding EPS core. Over time, the deck would develop a raised area adjacent to the SPRINGER HD, akin to the ‘ridging’ effect on a PU surfboard as the surrounding foam collapses on either side of the stringer.

We addressed this issue in two ways. Firstly, the SPRINGER HD stops approximately 3mm below the top deck, ensuring that the surrounding EPS compression will not lead to ‘ridging’. Utilizing our proven sandwich construction methodology, we also added an extremely durable material to the top deck of the board. This ‘deck-skin’ now serves as an additional buffer against the ridging effect while simultaneously working in tandem with the SPRINGER HD to optimize the overall flex pattern of the LFT build. The end result is a durable surfboard with lively flex patterns that will maintain its hi-performance characteristics over time.